Today when designing new products, buying and selling on a global level is more or less “mission critical” if companies are to achieve what they need to survive: grow sales, control costs in the supply chain, and employ the skills necessary to keep deploying new technologies to build smarter devices that will improve lives now and in the future. It is particularly true for high-tech companies serving post covid sectors such as healthcare, wellbeing, leisure, smart cities, automation and technologies to care for the environment.

Arguably, the facilities in place, such as trading agreements, communication links, and travel connections, make this easier than at any time in history. On the other hand, the complex blend of political and economic interests, mixed with social and technological change, is constantly shifting.

Even situations that seem relatively stable, such as the UK’s membership of the EU – which began in 1973 – can change suddenly and unexpectedly. As commercial organisations, we cannot control the circumstances. By operating intelligently, however, we can make the most of the opportunities and minimise the threats.

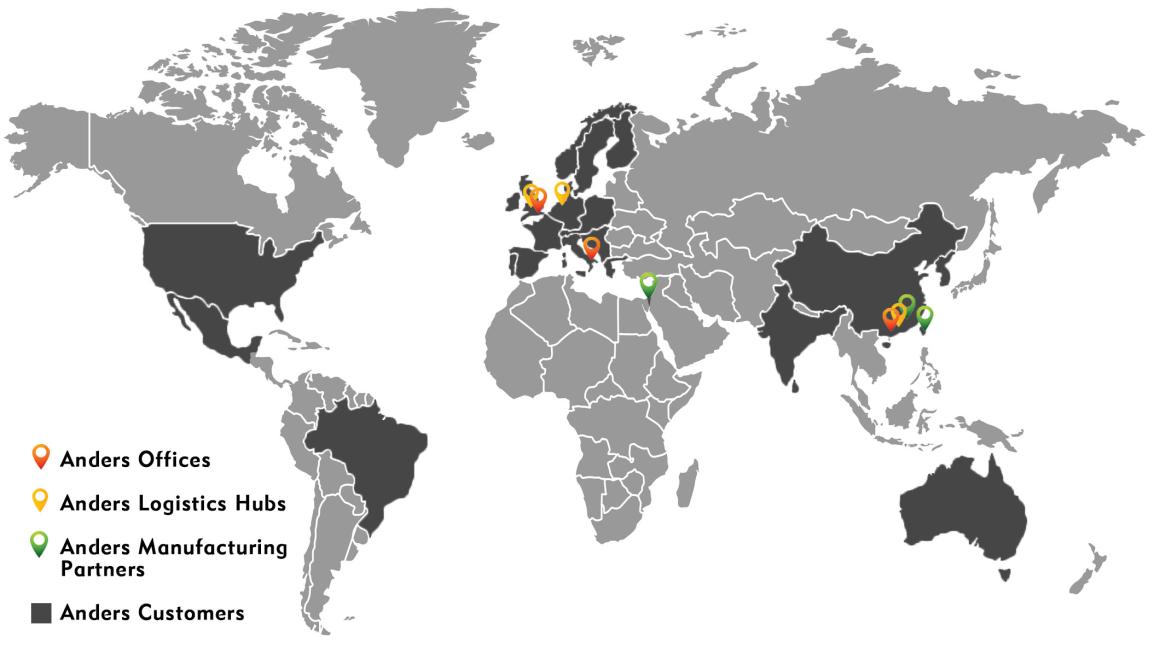

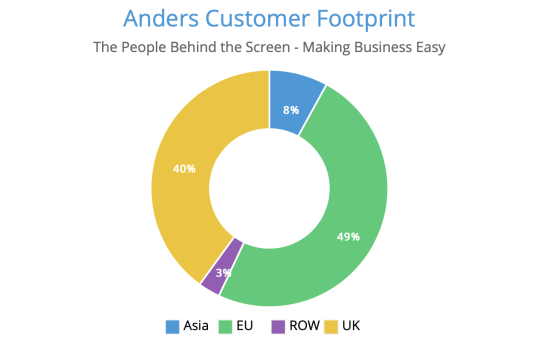

When I joined Anders 13 years ago, 85% of sales were in UK. Since then, sales to EU countries have overtaken UK sales.

To protect business post Brexit, we set up our new distribution hub in the Netherlands in 2019. This should help us continue to serve our customers in the EU as the trading position settles down and becomes better understood.

Changing Market Patterns

We have also strengthened our operations in Asia with the acquisition of Selectronic Ltd in 2020. Our Asia operations are based in Dongguan, the manufacturing centre and emerging high-tech innovation hub in the Guangdong, Hong Kong, Macao, Greater Bay Area. Our presence here enables us to work effectively with manufacturing partners and customers in Asia, benefiting from the business performance advantages gained by working in the same time, and language, as our suppliers and partners in the region. But China, today, must compete with other manufacturing destinations for inward foreign investment such as ASEAN countries. There are strong cases for onshoring, as well as outsourcing to locations such as central and eastern Europe and the Americas, India and electronic manufacturing services are thriving as a result.

International Relations

Our work with manufacturing partners in China also now takes place against the backdrop of the China-US and China-India trade wars, which have brought complications such as rising import duties and lengthening customs delays. These factors profoundly affect companies’ decisions regarding how to organise their supply chain to be as competitive as possible in their target markets. One example is Samsung’s recent investments in India, to begin display manufacturing in Uttar Pradesh. The move is intended to supply components to its nearby smartphone manufacturing plant in Noida and will undoubtedly draw other associated businesses to the region.

In addition to consumer products, India’s domestic high-tech markets place strong demand for devices to power smart infrastructure. Anders is engaging with local companies in India to explore the opportunities and the best ways to support potential partners and customers. Connecting like this with companies around the world is one of the most effective ways to evaluate market opportunities and risks, to get the information we need to make smart decisions.

We also maintain awareness of events that affect the locations where our customers operate and where their products are sold. Country of Origin strongly determines the customs import rules that apply.

Cultural Understanding

Our business mix is strategically designed to put our customer at the centre, with our business mantra of ‘easy to do business with’, at its core.

Engineering and Supply Chain account for nearly 50% of our organisation across the globe, as providing our customers’ with the expert care and attention they require, to take their product from design, to development, through to distribution requires skilled individuals and a personal approach.

The cosmopolitan nature of the Anders team, including those based at the UK office as well as in strategic locations throughout the world, gives us unique insights and flexibility to work across cultures and understand the factors that drive political and economic changes.

It enables us to tailor support for our customers in many countries, helping them deliver the services expected in their target markets.

And it is key to working effectively with our manufacturing partners across the world. Moreover, our multicultural diverse team unlocks innovation that drives business growth.

Adapting to new ways of working

The pandemic has tested the ability of businesses everywhere to adapt to new ways of working and changing market behaviour. From our point of view, markets for embedded equipment destined for sectors such as hospitality, entertainment, building, and retail have been severely affected. We have partnered with customers in these sectors for many years, so we acted to preserve those links by engaging with them to help overcome the challenges imposed by the situation and realign the supply chain where necessary.

On the other hand, industrial automation products, medical and healthcare technology, and small home appliances such as coffee machines, have remained stable or have grown. The rise in online shopping, the increased focus on mental and physical wellbeing, driven by the strict lockdowns in place across the world, has powered an increasing demand for embedded products for warehouse automation, which will likely continue to grow.

I suspect the buoyant sales of coffee machines are connected with the sudden transition to home-study and work-from-home (WFH), as schools and offices closed to minimise transmission. WFH has been critical to the survival of many companies – not to mention the personal finances of their employees.

At Anders, we have been working remotely since March 2020. Fortunately, we had already begun configuring our IT infrastructure for occasional remote working. We were able to leverage that head-start on the situation and our teams adapted quickly; like many, keeping in touch with colleagues, customers, and manufacturing partners by learning to use video conferencing at home. We have also enjoyed spending less time commuting.

With that said, we are looking forward to coming together as a team, in the same space, as restrictions hopefully start to lift soon.

In such a volatile world, we must protect our businesses and staff, look after our customers, and fulfil our responsibilities toward stakeholders. With so many variables in the mix, and the ever-present prospect of unexpected events such as Brexit and COVID-19, planning for the future may seem futile. The reality is that a properly conceived plan should be flexible and adaptive, as are people; and, that working together to overcome challenges brings us closer and makes us more resilient.