Quantum dot and microLED displays are being adopted in consumer products such as smartphones and televisions, as major brands strive to find an edge over their competitors. How do they compare with current technologies and can they bring meaningful improvements to industrial products?

Largest European MicroLED Display shown by Sony at ISE 2019, source: Installation International

Does my application look outdated?

Sooner or later, product designers need to upgrade the user interface of any application to improve its visual appeal. While changing fashions often drive revisions to consumer products, industrial technology tends to be shaped by form and function.

A competitor may have introduced a more modern-looking or attractive alternative. On the other hand, customer feedback may have requested improvements such as a wider viewing angle or longer runtime for battery-powered equipment.

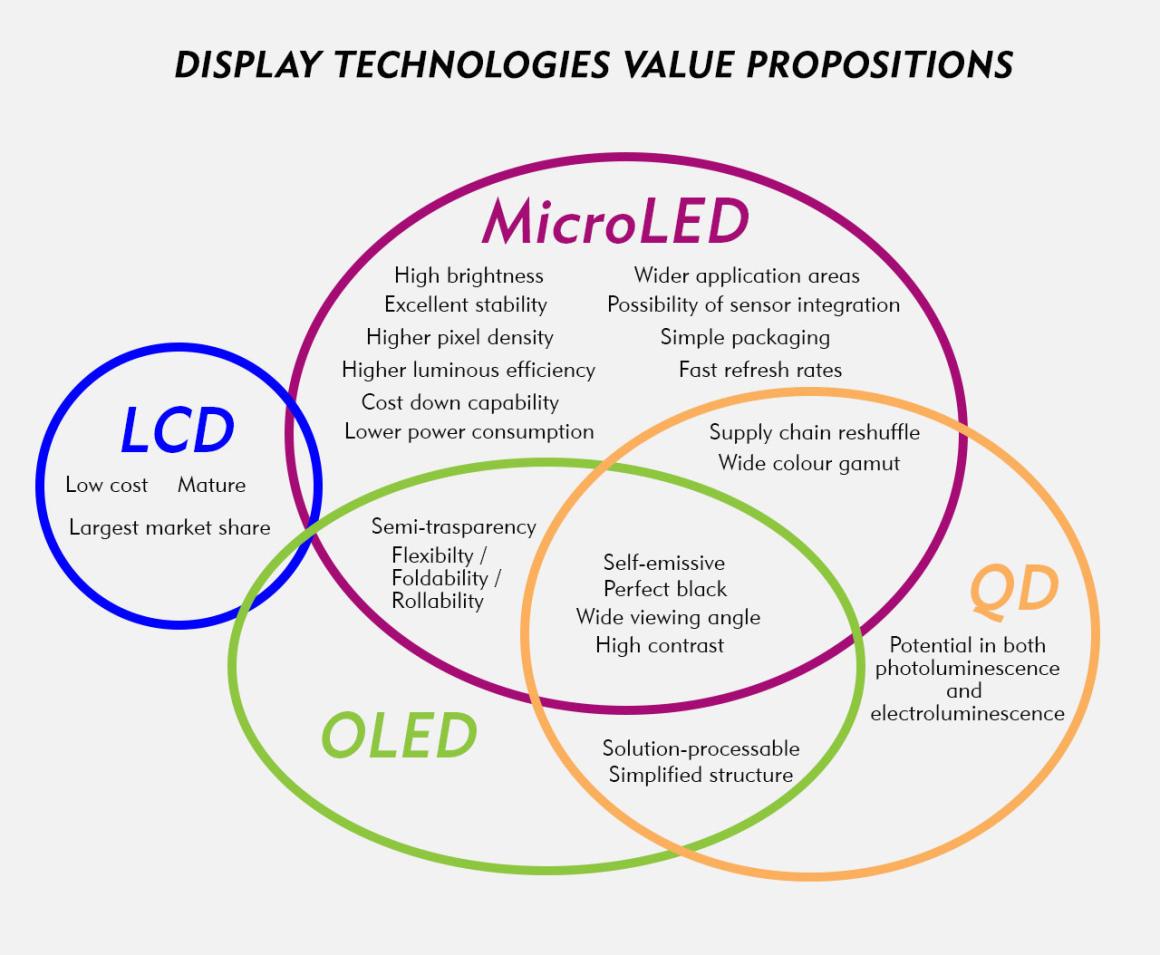

A higher performing display could be the best way to achieve the desired improvements. The latest technologies such as OLED, microLED, or quantum dot (QD) displays can offer superior colour and contrast, greater energy efficiency, and other qualities such as ultra-thin modules that can help save space and enhance portability. They also allow novel capabilities such as rollable or foldable displays.

What are the Best Display Technologies for Industrial Applications?

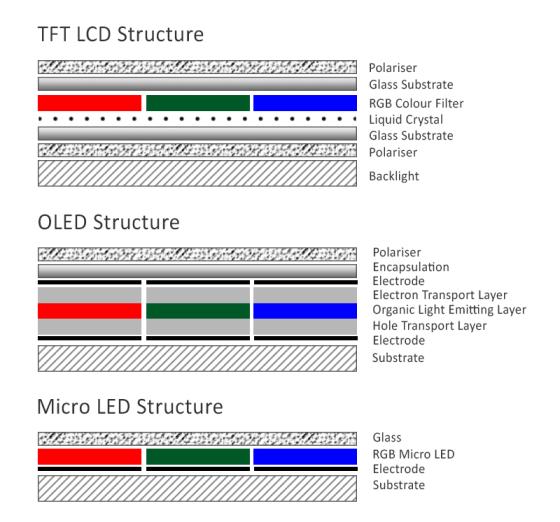

Right now, the proven TFT-LCD is the colour-display technology chosen for most industrial applications. Colourful and rugged, they have benefited from rapid technological improvement in recent years, through techniques such as In-Plane Switching (IPS aka Super-TFT), Advanced High Performance IPS (AH-IPS), and Advanced Dimension Switching (ADS), which increase viewing angles as well as enhancing colour quality and system efficiency, hence higher luminance. TFT-LCDs are also competitively priced, thanks in part to demands from the smartphone sector.

OLED/AMOLED displays are newer technologies that have been successful in consumer markets, currently replacing LCD as the most commonly used display technology in the smartphone sector. OLED televisions are projected to out-ship LCD models during 2021. However, while they offer some advantages, such as low power consumption and excellent colour rendition, with a high contrast ratio, the organic materials tend to degrade over time making them unsuited to industrial applications that are often expected to deliver service and reliability in the field for long periods, up to a decade or more. The blue-colour LEDs, in particular, are known to deteriorate relatively quickly.

What Alternative Display Technologies Offer Improvements over LCD?

Quantum Dot Colour Conversion (QDCC) has been successfully adopted to enhance both consumer LCD and OLED displays. Quantum dots are miniature semiconductor particles that emit light with a very narrow spectral distribution when photonically excited. They allow very pure RGB colours and precise tuning, resulting in richer colours, increased luminance, and greater contrast than a standard display. A wider viewing angle and higher energy efficiency can also be achieved.

Variants of the technology include Quantum Dot Enhancement Film (QDEF), which simplifies the manufacturing of displays enhanced with quantum dots. The most advanced quantum dot technology today is Quantum Nano Emitting Diode (QNED), which comprises rod-shaped nano-scale GaN LEDs that are printed by inkjet and aligned by electric field. Advantages include high efficiency and luminance, long lifetime, and freedom from burn-in.

Alternatively, microLED displays can offer great viewing characteristics, but there are practical and commercial challenges. The displays offer theoretically infinite contrast ratio and the non-organic technology does not suffer the degradation problems that restrict OLED’s industrial appeal. On the other hand, fabrication is time consuming and therefore expensive. A 4K display requires placing about 25 million individual LEDs, which takes about 1000 hours with state-of-the-art pick-and-place automation and demands sub-micron accuracy.

Before being considered for industrial applications, microLED must first succeed in consumer markets, which tend to be price sensitive. There is already intense competition between Chinese and Korean manufacturers, which could drive prices down and product shipments up. It’s one to watch, but too early to consider for forthcoming projects.

Get in touch to discuss these exciting new opportunities for your next generation display design.